What are Remote Phosphors?

The traditional and still preferred usage of phosphors in solid-state lighting involves pre-mixing powders with a polymer and directly depositing the phosphor particles on top of the LED die. The phosphor powders are mixed inside a cylindrical barrel/cartridge prior to dispensing pneumatically on LEDs. The dispensing method is currently used for a variety of reasons, but primarily due to its lower cost. However, such an approach results in lower LED wall plug efficiency (WPE) due to (1) optical scattering losses and (2) light trapping and total internal reflection (TIR) losses within the phosphor/polymer matrix.

LEDs produced using the traditional approach suffer from color uniformity with angle as a result of the limited control of phosphor distribution and packing density on top of the die. Furthermore, as LED power increases, this method becomes even more limited due to the significant thermal and optical load on the silicone/phosphor matrix. This leads to further drop in efficiency and performance at higher temperatures and power densities. The performance issues can be illustrated, for example, by the recent wave of purple LED street lights emerging around the globe where the color of the original white LEDs have degraded into bluish-purple colors. These are some of the primary reasons why the remote phosphor approach is used in high end specialty fixtures, despite the higher material usage/costs involved.

High Quality Lighting

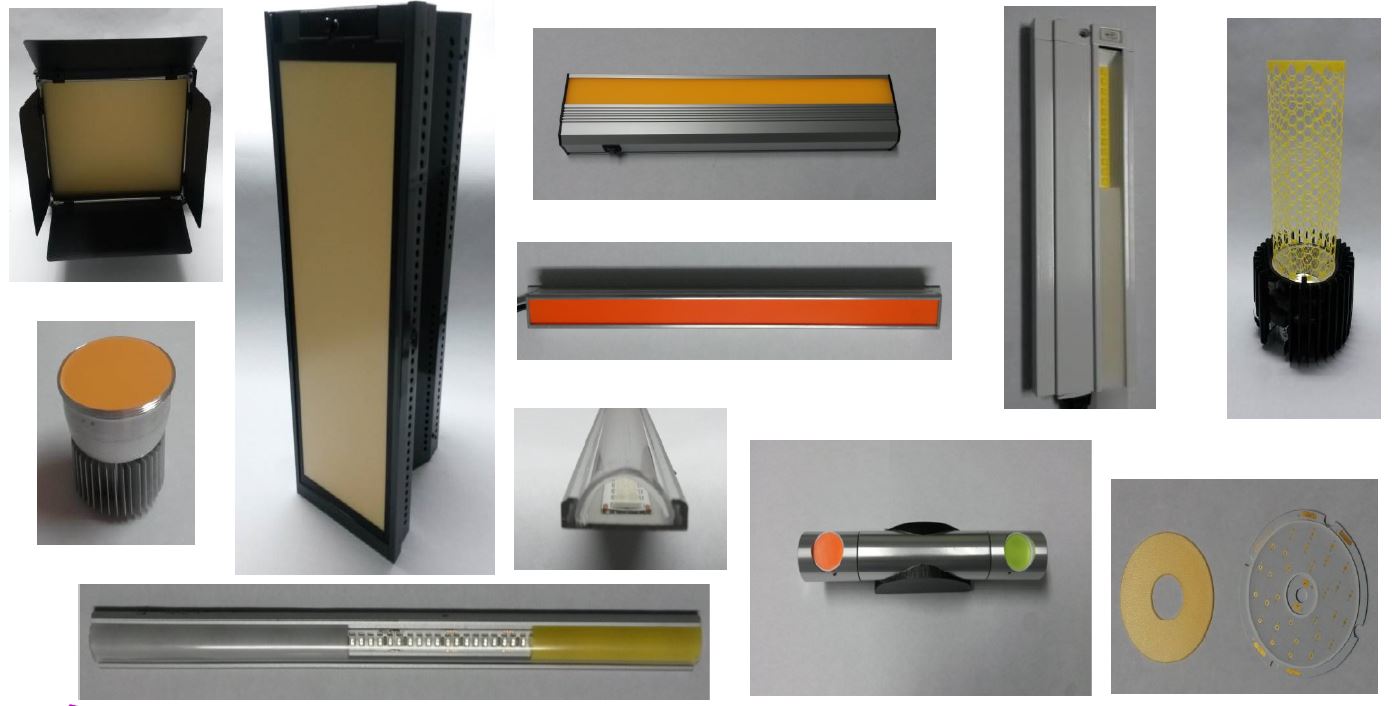

Another major advantage of remote phosphor technology is the elimination of pixelated light sources and multiple shadows. Such a problem is common in most linear LED-based fixtures on the market today. The use of a remote phosphor plate transforms a pixelated LED with a narrow emission angle into a more appealing light source with a Lambertian emission pattern. In addition, remote phosphors enable a higher degree of color control and lead to light fixtures with very high color quality and color rendition (CRI). These effects are illustrated in the below figure which compares a conventional 12inch LED fixture (Left) to a 12inch linear fixture utilizing remote phosphors technology from PhosphorTech.

Traditional (pixelated) 12in LED lamp (left) and a remote phosphor 12in LED lamp (right)