Phosphor-converted LEDs or pcLEDs are a class of light-emitting devices that combine narrow-band solid-state light emitters with phosphor materials. The result is generally a broadband light source and an ability to customize the color of light beyond what can be achieved with LED technology alone. The vast majority of white LED bulbs and fixtures on the market today employ pcLEDs to produce white light in a wide range of color temperature such as daylight, neutral white, and warm white. The use of phosphors in LED bulbs is also necessary to achieve high color rendition. In display applications, pcLEDs are also used in backlights in order to achieve a wide color gamut and high color quality.

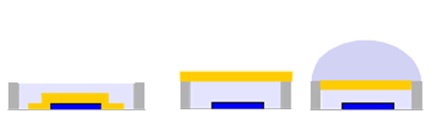

White LEDs can be manufactured using either blue- or near-ultraviolet (near-UV) semiconductor chips coated with a yellow phosphor powder (pcLEDs), or using red-green-blue (RGB) systems that mix light from multiple monochromatic LEDs. One problem with mixing light from multiple LEDs is that it requires separate electronic drivers since different color LEDs are driven at different voltages and currents. Another problem stems from the highly directional nature of LED light, which requires additional optics for good color mixing. On the other hand, phosphor-converted LEDs work by combining one or several phosphors with one type of LEDs (blue or near-UV). This makes the technology of pcLEDs a much simpler and a more economical approach for producing different colors including cyan, green, yellow, orange, red, and white (broadband light). Even near-infrared light can be produced using monochromatic LEDs combined with specific phosphor systems. Another advantage of the pcLED approach is that the phosphor does not need to be integrated or encapsulated within the LED device. By placing the phosphor material or film external to the LED package or even remote, the user or lighting designer has the ability to customize the color of light to a wide range of applications.

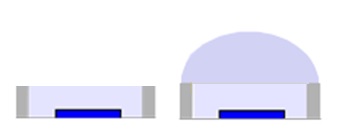

Monochromatic (single color) LEDs

Phosphor-converted LEDs