Powder Material Testing

Material testing of phosphors or any other powder materials (luminescent or non-luminescent) is generally done using a variety of instrumentation and procedures, depending on the properties that need to be investigated.

One of the most common types of testing conducted on materials in particle form is the particle size distribution test or PSD. Laser diffraction is generally used for particle sizes between 0.1 microns to several hundreds of microns. Scanning electron microscopy (SEM) is used to examine the particle shape and morphology while Energy-dispersive X-ray spectroscopy (EDX) or X-ray fluorescence (XRF) are used for the chemical identification of elements and their concentration. X-Ray diffraction (XRD) is also used for phase identification.

The adsorption properties of powders and catalyst materials to various surfactants, pigments, liquids, contaminants, or gases can also be measured using specialized spectroscopy instrumentation that operate across the UV/Vis and infrared parts of the spectrum.

Nanocrystal Testing

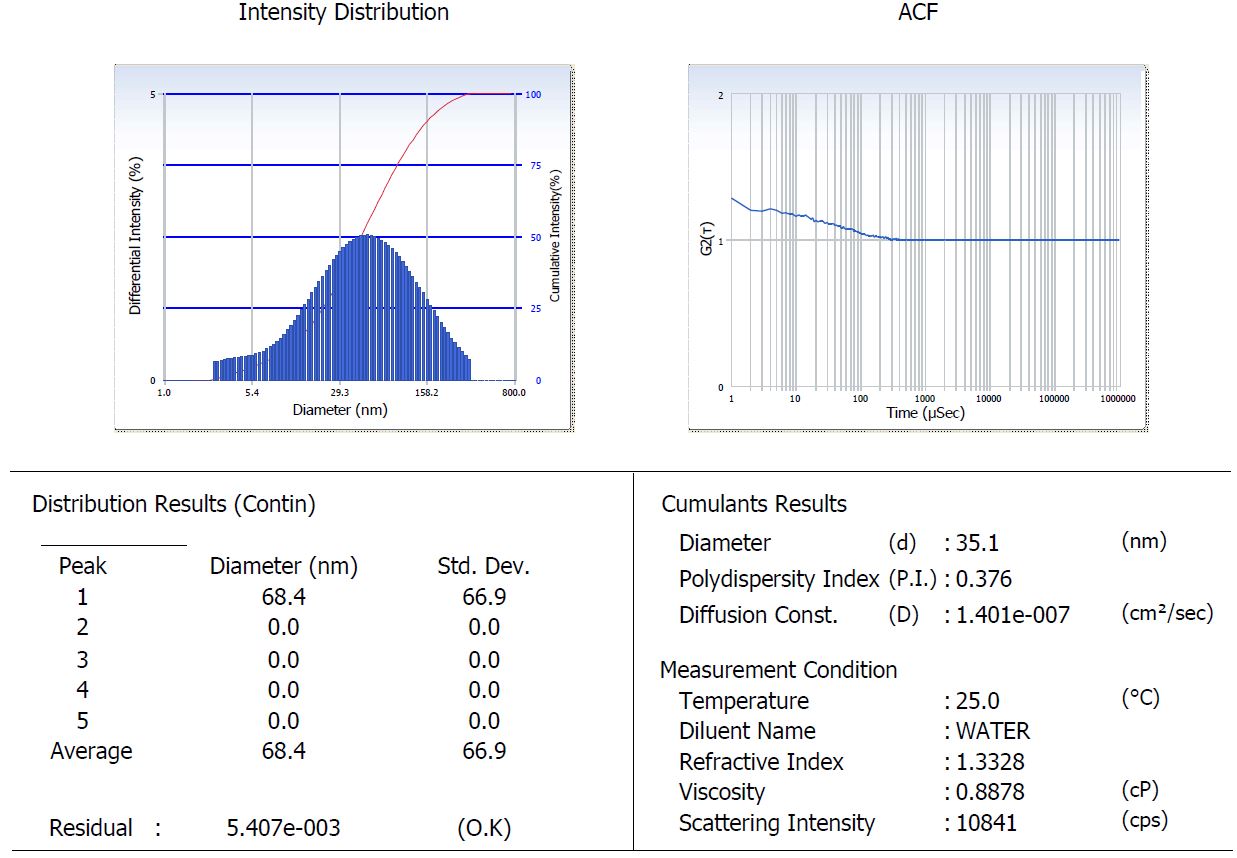

Dynamic light scattering (DLS) is used mostly for determining average size and distribution of smaller nano-size particles but can also measure materials of few microns in size. DLS can also be used to measure Zeta potential of colloidal solutions. Transmission electron microscopy (TEM) is generally used to examine the morphology of nanocrystal particles while EDX and XRF can also be used to determine composition information.