WHAT ARE PHOSPHORS?

Phosphors in general are materials that emit light upon absorbing incident energy. They have a broad range of light color emissions and can absorb and convert energy from various forms such as optical, electrical, even mechanical or thermal. The term “scintillator” is sometimes used to describe phosphors that produce luminescence when excited by ionizing radiation.

Phosphors for Lighting and Display Technologies

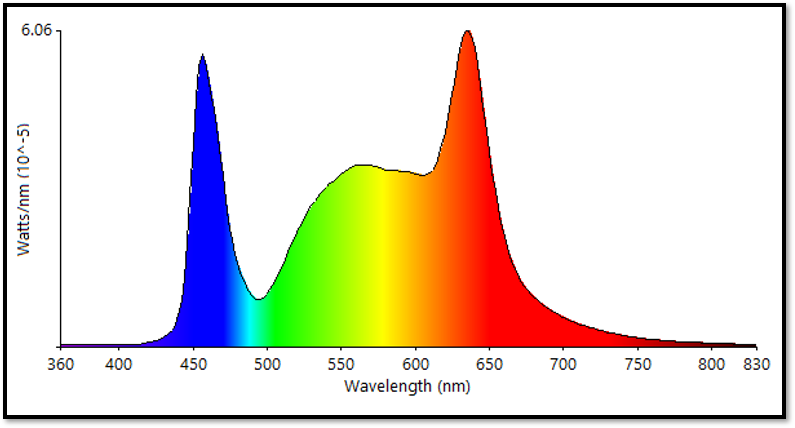

Phosphors are the most popular choice as color emitters and converters in most lighting and display technologies. In solid-state lighting, LED phosphors (also known as down-converters or luminophores) have been utilized to convert ultraviolet, violet or blue light (usually from a semiconductor light-emitting diode or laser) into colors of lower energy. Depending on the specific LED or laser architecture and power levels, phosphor powders can be encapsulated in polymers (silicone/epoxy), or glass and ceramic. Visible phosphor emission colors range from violet/blue to deep red. Some can also absorb and emit energy in the non-visible spectral regions such as ultraviolet and infrared. Nanophosphors and quantum dots (QDs) are also color emitters that have small size particles at the sub-micron or nano-scale. Upconversion phosphors that operate via anti-Stokes fluorescence can absorb multiple low energy photons while emitting higher energy photons. Electroluminescent (EL) phosphors can directly produce light from AC or DC electrical current while cathodoluminescent (CL) phosphors can produce light when excited by electrons energized in vacuum.

Learn more about phosphor applications on PhosphorTech’s Technology page.

How is a Phosphor Made?

Phosphors are usually made using a stable inert host material (typically oxides, nitrides, silicates, sulfides, or selenides) doped in small quantities with activators (such as metal or rare earth ions), which create non-homogeneities or impurities in the crystal structure enabling the emission of light. These impurity centers capture the excitation energy and then release it in the form of light. The type and concentration of the dopant(s) generally determine the color of the emitted light.

Phosphors are usually made using a stable inert host material (typically oxides, nitrides, silicates, sulfides, or selenides) doped in small quantities with activators (such as metal or rare earth ions), which create non-homogeneities or impurities in the crystal structure enabling the emission of light. These impurity centers capture the excitation energy and then release it in the form of light. The type and concentration of the dopant(s) generally determine the color of the emitted light.

Characteristics of LED Phosphors

- Can be highly efficient as light emitters and down-converters

- Are relatively inexpensive compared to other methods of producing multi-colors from LEDs

- Can be made thermally and chemically stable with long shelf and operational lifetime

- Are easy to handle/process and can be made to be environmentally friendly

Due to these desirable properties, phosphors also find applications in a variety of devices ranging from more traditional lighting systems to X-ray imaging and radiation scintillators/detectors.

Phosphors are usually made using a stable inert host material (typically oxides, nitrides, silicates, sulfides, or selenides) doped in small quantities with activators (such as metal or rare earth ions), which create non-homogeneities or impurities in the crystal structure enabling the emission of light. These impurity centers capture the excitation energy and then release it in the form of light. The type and concentration of the dopant(s) generally determine the color of the emitted light.

Characteristics of LED Phosphors

- Can be highly efficient as light emitters and down-converters

- Are relatively inexpensive compared to other methods of producing multi-colors from LEDs

- Can be made thermally and chemically stable with long shelf and operational lifetime

- Are easy to handle/process and can be made to be environmentally friendly

Due to these desirable properties, phosphors also find applications in a variety of devices ranging from more traditional lighting systems to X-ray imaging and radiation scintillators/detectors.

Solid State Lighting (SSL) and White LEDs

Over the past 50 years, many types of phosphors have been developed to cater to the needs of various types of applications. Among all the various applications, the biggest recent impact of phosphors has been on the solid-state lighting (SSL) industry. Particularly, the use of phosphors with light-emitting diodes (LEDs) or lasers have recently led to the rapid development of highly efficient white lamps with high color rendition (CRI) and a wide range of color temperatures (CCTs), including full spectrum lighting and solar simulators. These developments have helped push SSL technology to be the next generation alternative to compact fluorescent lamps and the inefficient incandescent bulbs.

Learn more about solid state lighting applications on the PhosphorTech website.

Phosphor Types

Some of the most common types of phosphors available are:

- Rare earth doped aluminates – Y3Al5O12:Ce3+

- Rare earth doped orthosilicates – (Ba,Sr,Ca)2SiO4:Eu

- Rare earth doped nitrides – (Sr,Ca)2Si5N8:Eu and (Sr,Ca)Si2O2N2:Eu

- Rare earth doped chlorosilicates – Ca(8-x)Eux(Mg,Mn)(SiO4)4Cl2

- Rare earth doped thiogallates – (Sr,Ca,Ba)Gax(S,Se)y:Eu

- Transition metal doped sulfo selenides – ZnSexS(1-x):Cu

While Ce and Eu are the most common dopants used in phosphors, other lanthanide ions such as Pr3+, Tb3+ and Er3+ can also be found in some compositions. There are additionally hundreds of other types of phosphors available being used for a wide rage of applications, such as phosphor thermometry and anti-counterfeiting security, for example. A detailed but partial list of phosphors by color, type, and application can be found here.

Product Development: Customizing Phosphors for Specific Applications & Fixtures

None of the above individual phosphors offer a complete solution for all LED configurations or color applications. All have their advantages and disadvantages. Phosphor material experts can help design and select combinations of the above materials in order to achieve the required luminous efficiency (lumens/watt or LPW), chromaticity coordinates (CIE), color rendering index (CRI), and color temperature (CCT) demanded by a given application.

Learn more about product development on the PhosphorTech website.

Research, Testing and Development with Phosphors

Phosphor material experts also help investigate the operational limits of these materials and develop techniques for processing and coating on LEDs or lamp fixture components in such a way as to improve both the phosphor and LED lamp performance under extreme operating conditions. A wide range of measurement techniques and instrumentation are available for material testing and development.

Learn more about research and development on the PhosphorTech website.

Phosphor Integration with LEDs, MicroLEDs and Flexible Electronics

Phosphor material experts can also help integrate and deposit these materials on a wide range of LEDs or light engine components in addition to exploring their many use in optoelectronics, photovoltaics, medical/dental, and flexible electronics.

Learn more about phosphors and photonics on the PhosphorTech website.

For example, in LED devices, phosphors can be configured for use directly on 1) the blue/UV chip, 2) on the package, or 3) even remotely with the blue LED sources.